- Model: JKH-130

- Bowl and tray material: 304 stainless steel

- Pressure plate material: Aluminium

- Plate diameter: 130mm

- Meat allowance: 80-260g

- Meat patty thickness: 14mm(200g)20mm(250g)22mm(260g)

- N.W/G.W: 4.7kg/6kg

- Packing size: 280x230x310mm

- Product size: 225x210x290mm

JKH-130 Hot Sale Meat Pie Molding Machine: Precision in Every Patty

The Ultimate Solution for Meat Patty and Chicken Nugget Production

The JKH-130 Hot Sale Meat Pie Molding Machine is designed to streamline the production of consistent, high-quality meat pies, hamburger patties, and chicken nuggets. Whether you're running a commercial kitchen or a small food business, this versatile machine guarantees efficient, uniform results every time. With its easy-to-use manual operation, the JKH-130 Patty Maker is perfect for businesses looking to improve their production efficiency while maintaining top-notch quality.

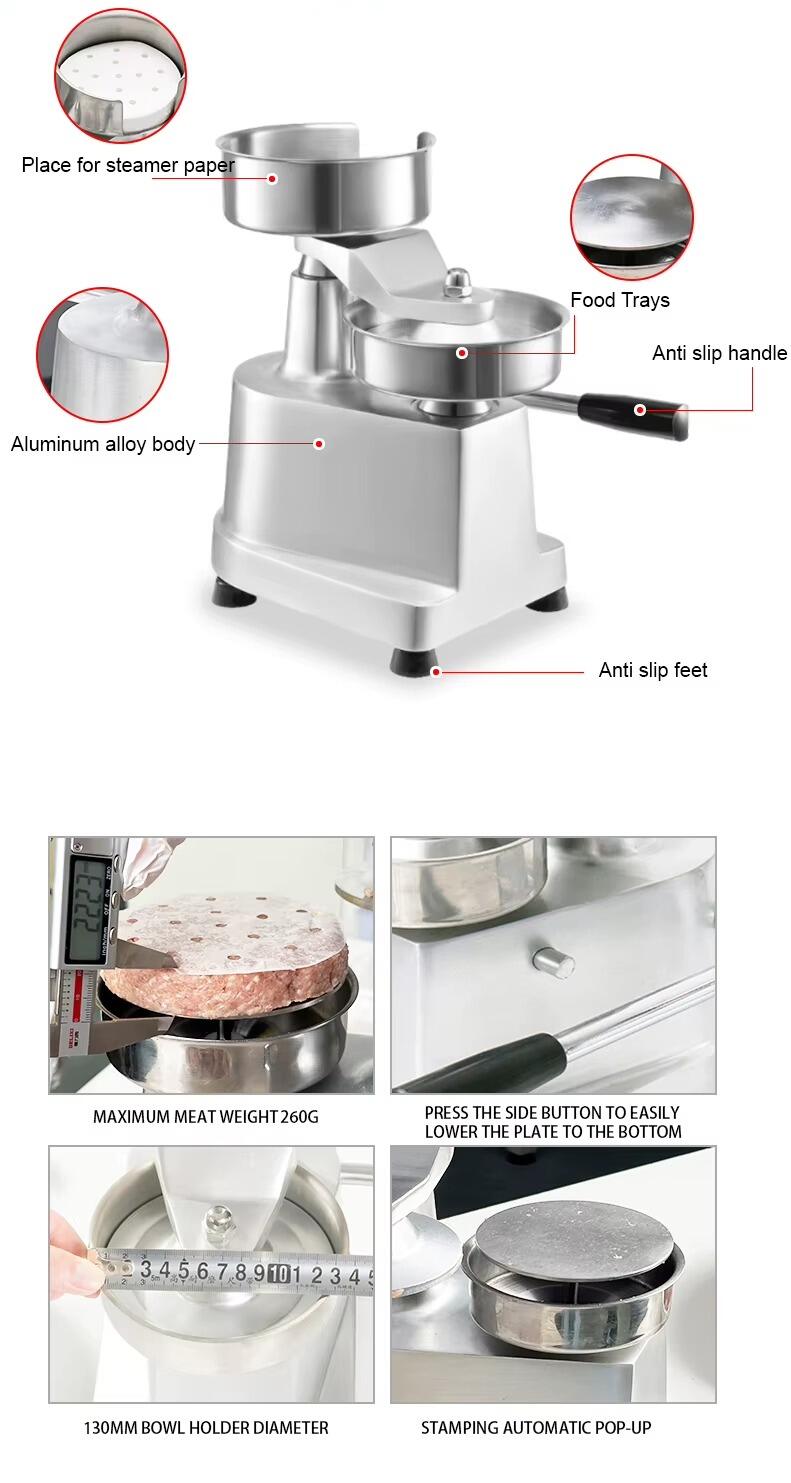

Key Features of the JKH-130 Patty Press

1. High-Quality Construction for Durability

The JKH-130 Patty Maker is built to last with high-quality materials. The 304 stainless steel used in the bowl and tray ensures corrosion resistance and easy cleaning, making the machine suitable for long-term use in demanding environments. The aluminum pressure plate is designed for optimal performance, offering strength without adding unnecessary weight. This combination of materials ensures that the JKH-130 can withstand heavy usage in both commercial and home kitchens.

2. Precision and Consistency in Patty Formation

This meat patty maker features a plate diameter of 130mm, allowing you to create patties and meat pies with consistent size and shape. The meat allowance ranges from 80g to 260g, providing flexibility for different portion sizes. The machine is capable of creating meat patty thicknesses of 14mm (200g), 20mm (250g), and 22mm (260g), giving you the ability to adjust the thickness to suit your specific needs. With the automatic pop-up feature, the machine ensures easy and efficient patty formation every time.

3. One-Time Stamping and Forming Process

The JKH-130 Patty Press is designed to maximize efficiency by using a one-time stamping and forming process. This means that once the meat is placed in the machine, it is quickly and precisely pressed into the desired shape and thickness. The automatic pop-up feature ensures that the patty is ejected from the machine smoothly, ready for cooking or storage. This streamlined process significantly reduces labor time and increases overall productivity in high-demand environments.

4. Easy to Operate and Maintain

The JKH-130 Patty Maker is equipped with a side button that allows you to easily lower the plate to the bottom for precise patty formation. The machine’s compact design and simple operation make it accessible for both novice and experienced users. The easy-to-clean components ensure that maintenance is a breeze. The machine's 304 stainless steel components resist food buildup, making it quick to wipe down after use, ensuring that hygiene standards are always met.

Advantages

1. Increased Efficiency and Output

One of the major advantages of the JKH-130 Patty Maker is its ability to increase production efficiency. With the automatic pop-up mechanism and one-time forming process, this machine can produce a large number of patties, pies, or nuggets in a short period of time. This is particularly beneficial for high-volume production in commercial kitchens, catering services, or any business that requires large quantities of meat-based products to be prepared quickly and consistently.

2. Customizable Portion Sizes and Thickness

The JKH-130 offers a high degree of customization with its adjustable meat allowance and patty thickness options. Whether you're making small meat pies or larger hamburger patties, this machine allows you to easily adjust the portion size to meet the demands of your business or personal preferences. The machine’s ability to handle a range of meat weights (80g to 260g) gives you flexibility in preparing different menu items, from sliders to full-sized burgers or chicken nuggets.

3. Durability and Longevity

The 304 stainless steel construction of the JKH-130 Patty Maker ensures that the machine will stand the test of time, even in demanding environments. Stainless steel is known for its resistance to rust, corrosion, and staining, which makes it ideal for food machinery that requires regular cleaning. The aluminum pressure plate adds strength and ensures that the machine operates smoothly, even with frequent use.

4. User-Friendly Operation

The JKH-130 Patty Press is designed with simplicity in mind. Its side button mechanism allows easy lowering of the plate, reducing the effort required to operate the machine. The compact size of the machine makes it easy to store and maneuver, making it suitable for both commercial and home kitchen use. Its lightweight design (only 4.7kg) ensures that it is portable and can be moved around as needed.

Applications

1. Commercial Kitchens and Restaurants

In a commercial kitchen, the JKH-130 Patty Maker is an invaluable tool for creating consistent, high-quality products quickly. Whether you're serving meat pies, hamburgers, or chicken nuggets, this machine ensures that every item meets the same high standards of size, shape, and thickness. It is particularly useful in restaurants, fast food chains, and catering businesses that require efficient mass production of meat-based products.

2. Catering Services and Events

For catering services or businesses hosting events, the JKH-130 can quickly produce a large quantity of uniform meat patties or nuggets. Whether you're catering a wedding, a corporate event, or a large festival, the ability to adjust portion sizes and thickness allows you to meet diverse customer needs while ensuring quick service and high-quality food.

3. Home Kitchens and Small Businesses

The JKH-130 Patty Maker is not just for commercial kitchens—it is also ideal for home kitchens or small-scale food businesses. Whether you're preparing burgers for a BBQ or making homemade chicken nuggets, the JKH-130 allows you to achieve professional-level results at home. Its ease of use and simple maintenance make it an excellent tool for anyone looking to elevate their cooking game.

Why Choose the JKH-130 Patty Maker?

Durability: Constructed from 304 stainless steel and aluminum, the JKH-130 is built to last and can withstand frequent use in demanding environments.

Efficiency: The one-time stamping and forming process allows you to create high volumes of patties quickly, increasing productivity in commercial kitchens.

Customizable: With adjustable meat allowance and patty thickness, you can customize your products to suit different customer needs.

User-Friendly: Simple operation and easy maintenance make the JKH-130 suitable for both beginners and experienced users.

Compact and Lightweight: The compact size and lightweight design make it easy to store and transport, perfect for both small and large kitchens.

Conclusion: Invest in the JKH-130 Patty Maker for Efficient, Consistent Production

The JKH-130 Hot Sale Meat Pie Molding Machine is the ideal solution for anyone looking to streamline their production of meat pies, hamburgers, chicken nuggets, or any other meat-based product. Its durable construction, efficient design, and customizable options make it perfect for both commercial and home kitchens. With the JKH-130, you can expect consistent results, increased productivity, and high-quality products every time.

|

Model:

|

JKH-130

|

|

Bowl and tray material:

|

304 stainless steel

|

|

Pressure plate material:

|

Aluminium

|

|

Plate diameter:

|

130mm

|

|

Meat allowance:

|

80-260g

|

|

Meat patty thickness:

|

14mm(200g)20mm(250g) 22mm(260g)

|

|

N.W/G.W:

|

4.7kg/6kg

|

|

Packing size:

|

280x230x310mm

|

|

Product size:

|

225x210x290mm

|

Q1. What is the amount of meat foam that can be added?

Our hamburger machine series can hold around 50-350g of minced meat.

Q2. What is the minimum order quantity? Can accessories be purchased separately?

Minimum order quantity is 1 unit, and our accessories can be ordered separately.

Q3. Is there any stock available for the delivery time of orders and sample orders?

1-5 units of stock products will take approximately 5 days, and multiple units or customized products will be negotiated based on your order specifications and quantity.

Q4. Can I take samples for market testing?

yes. Sample orders can be used for quality inspection and market testing.

Q5. What is your payment method?

Payment methods: T/T, L/C at sight, WeChat, Paypal, Trade Assurance, Alipay, Applepay, VISA, UnionPay, etc.

Q6. What are your warranty terms?

Remote warranty for one year, quality issues, free accessories provided, consumable accessories are not covered by the warranty.

Q7. How many types of plugs are there to choose from?

Australian plug, English plug, American plug, European plug, etc., customized according to your needs.

Q8. What material is the packaging box made of?

You can choose between non boxed and cardboard boxes independently.

Q9. How does your factory do quality control?

We attach great importance to quality control from beginning to end. Each product undergoes 100% comprehensive testing before packaging and shipping.

Q10. What are your payment terms?

100% full payment before production.

Copyright © by Changzhou Jinkun Food Machinery Co., Ltd. - Privacy Policy