- Model: ECO-32S no shell

- Power: 2.2kw

- Volatge: 220v

- Rated frequency: 50hz/60hz

- Production: 320kg

- N.W/G.W: 33.5/38.5kg

- Meat grinding efficiency: 320kg/h

- Machine material: 304 stainless steel

- Orifice plate diameter: 6mm/8mm

The ECO-32S High-Power Meat Grinder is designed for high-volume meat processing in commercial kitchens, butcher shops, and food production facilities. With a robust 2.2KW motor and a production rate of 320 kg/h, this stainless steel grinder efficiently handles large quantities of meat, providing fast, precise results every time. Whether you’re grinding fresh meat, frozen meat, or even tougher cuts, the ECO-32S offers unparalleled performance, durability, and ease of use.

Key Features of the ECO-32S High-Power Meat Grinder

1. Powerful 2.2KW Motor: The ECO-32S is equipped with a high-performance 2.2KW motor, delivering exceptional power to grind up to 320 kg of meat per hour. Whether you're working with fresh or frozen meat, this motor ensures consistent, high-efficiency grinding, even under demanding conditions.

2. 304 Stainless Steel Construction: Built with high-quality 304 stainless steel, the ECO-32S is designed for durability, rust-resistance, and easy cleaning. The stainless steel construction ensures that the machine remains hygienic and maintains its strength and appearance, even after prolonged use.

3. Sharp Blades for Efficiency: The grinder comes with two sets of blades (6mm and 8mm orifice plate blades), designed to handle various types of meat. The sharp blades allow for fast, smooth grinding, even when working with frozen or tougher cuts of meat. This versatility makes the ECO-32S ideal for a range of meat processing tasks.

4. Large Meat Inlet: The ECO-32S features a large meat inlet diameter of 70mm, making it easier to feed larger cuts of meat into the machine. The increased diameter reduces the need for pre-cutting, saving valuable time in busy environments.

5. Easy-to-Clean Design: One of the standout features of the ECO-32S is its ease of cleaning. The 304 stainless steel parts are simple to disassemble and clean, ensuring a hygienic and efficient processing environment. This feature is particularly important for businesses that prioritize food safety and cleanliness.

6.Wooden Box Packaging: The ECO-32S is packaged securely in a wooden box, ensuring it arrives at your location in perfect condition. The packaging is designed to protect the machine during shipping, reducing the risk of damage.

Advantages

1. High-Performance Grinding: With a motor capable of processing 320 kg of meat per hour, the ECO-32S delivers the high grinding capacity needed for commercial kitchens, butcher shops, and food production facilities. Whether you're grinding beef, pork, or poultry, this grinder will keep up with high-demand environments without compromising on quality.

2. Durability and Longevity: The 304 stainless steel construction ensures that the ECO-32S is built to last. Its rust-resistant and easy-to-clean design means it will continue to perform efficiently for years, even under heavy use. This durability makes the ECO-32S a reliable investment for businesses in the food industry.

3. Versatility in Meat Types: The ECO-32S is designed to handle a wide range of meat types, including fresh, frozen, and tough cuts. The two sets of sharp blades (6mm and 8mm orifice plates) make it suitable for grinding different textures and consistencies, providing greater flexibility for your food preparation needs.

4. Time-Saving Efficiency: The large meat inlet (70mm) allows for faster processing, as you won’t need to spend extra time cutting large pieces of meat into smaller chunks. This increased efficiency leads to quicker turnaround times, which is especially important in high-volume food processing environments.

5. Hygienic and Easy to Maintain: Cleaning the ECO-32S is a breeze. The machine's design allows for quick disassembly and thorough cleaning, helping you maintain a sanitary working environment. This ease of maintenance is vital for businesses that adhere to strict food safety regulations.

Customizable Options: The ECO-32S offers customizable features to meet the specific needs of different businesses. Whether you require a particular blade size, voltage, or other specifications, this grinder can be tailored to suit your requirements, ensuring optimal performance for your food processing tasks.

Applications

The ECO-32S High-Power Meat Grinder is suitable for a wide range of applications across various industries. Here are some of its key uses:1. Commercial Kitchens: The powerful motor and high grinding capacity of the ECO-32S make it an ideal tool for large-scale kitchens that need to process a large volume of meat. This includes restaurants, catering businesses, and hotels, where fresh ground meat is required on a daily basis.

2. Butcher Shops: For butcher shops that need to grind meat regularly, the ECO-32S offers an efficient solution. Its sharp blades and high processing capacity allow butchers to grind meat quickly, meeting customer demands while maintaining high-quality standards.

3. Food Processing Plants: The ECO-32S is perfect for food manufacturing facilities that process large quantities of meat for packaged products or ready-made meals. With its ability to grind up to 320 kg/h, it can handle the high demands of food production lines.

4. Supermarkets: In supermarkets with in-house butchery sections, the ECO-32S provides a quick, efficient way to prepare fresh ground meat for customers. Its large meat inlet and high capacity allow for seamless operation in high-traffic areas.

5. Sausage and Minced Meat Preparation: The ECO-32S is ideal for businesses that specialize in sausages, minced meat, or meat patties. The customizable blades allow for different textures, making it easier to prepare products like sausages, burgers, or ground beef with consistent results.

6. Frozen Meat Grinding: The sharp blades of the ECO-32S allow it to handle frozen meat without issue. Whether you’re working with pre-frozen cuts or need to grind frozen meat for specific recipes, this grinder can deliver the performance you need.

Installation Process

Setting up the ECO-32S Meat Grinder is straightforward. Follow these simple steps to get started:

1. Insert the Three-Way Connector: Attach the three-way connector to the grinder’s components to ensure a secure fit.

2. Place the Auger Inside: Insert the auger into the machine, ensuring it is properly aligned for optimal grinding performance.

3. Insert the Blades: Place the appropriate blade (6mm or 8mm) into the machine, making sure it is securely attached.

4. Attach the Sieve: Finally, insert the sieve into place, completing the installation process.

Once assembled, the ECO-32S is ready to go. The installation process is quick and simple, allowing you to begin processing meat without delay.

Why Choose the ECO-32S?

Changzhou Jinkun Food Machinery Co., Ltd. has been a trusted name in the food machinery industry since its founding in 2012. Our commitment to quality and innovation has earned us multiple certifications, including CE, and we export to over 100 countries worldwide. With our professional team dedicated to new product development and stringent quality control, we ensure that each product meets the highest standards.

The ECO-32S High-Power Meat Grinder is a perfect example of our dedication to providing reliable, high-performance equipment. Whether you're in the food service industry, a butcher shop, or a large-scale food production facility, this grinder offers the power, efficiency, and durability needed to meet your meat processing demands.

|

Model:

|

ECO-32S no shell

|

|

Power:

|

2.2kw

|

|

Volatge:

|

220v

|

|

Rated frequency:

|

50hz/60hz

|

|

Production:

|

320kg

|

|

N.W/G.W:

|

33.5/38.5kg

|

|

Meat grinding efficiency:

|

320kg/h

|

|

Machine material

|

304 stainless steel

|

|

Orifice plate diameter:

|

6mm/8mm

|

|

Diameter of meat inlet(plate):

|

60mm

|

|

Diameter of meat inlet(machine):

|

70mm

|

|

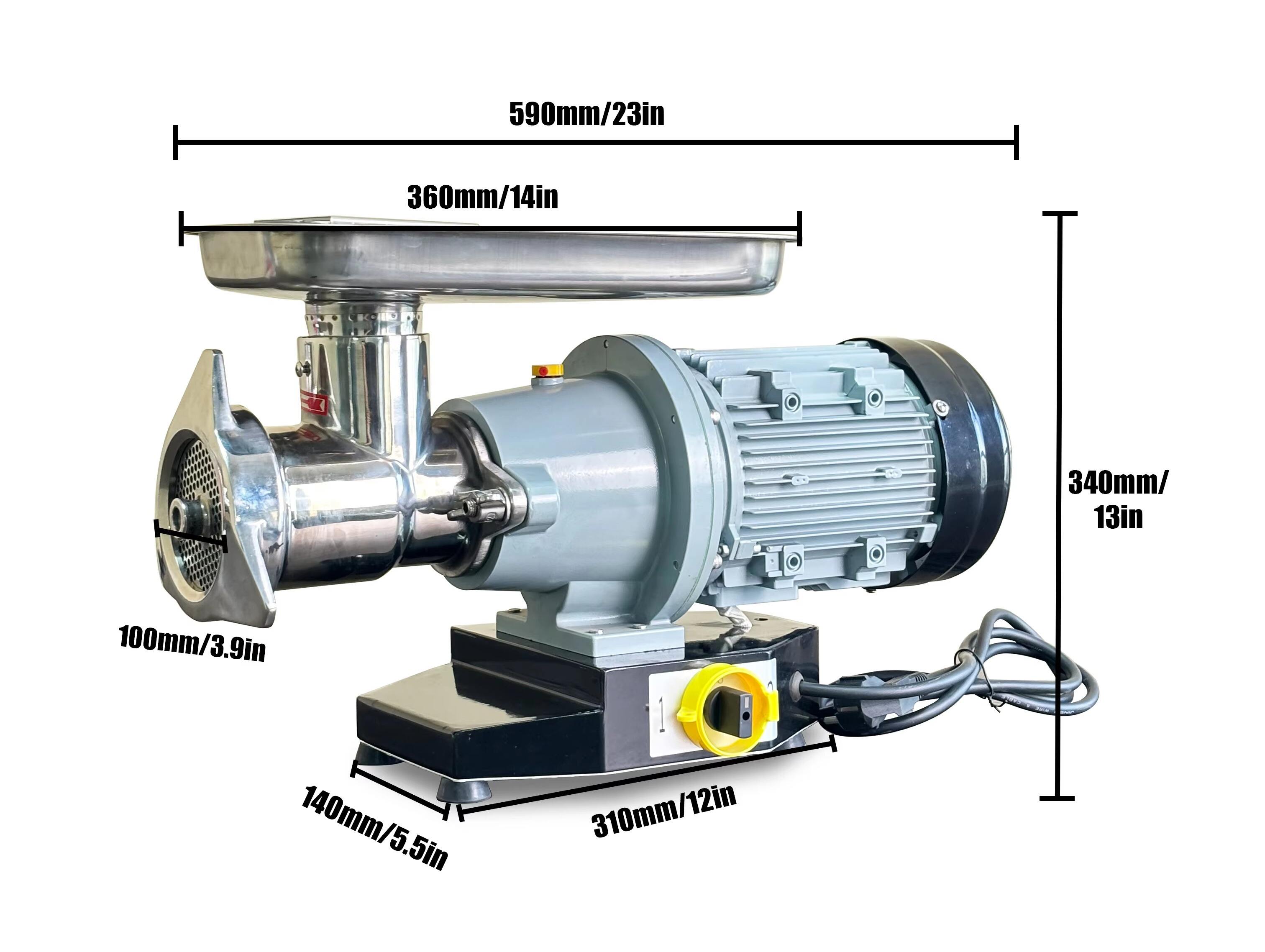

Product size:

|

565*260*340mm

|

|

Package size:

|

640*350*460mm

|

Q1. Which foods are suitable and can fresh meat be cut?

Our slicer series can cut frozen meat (excluding bones), vegetables, fruits, sausages, etc. It is not recommended to cut fresh meat.

Q2. What is the minimum order quantity? Can accessories be purchased separately?

Minimum order quantity is 1 unit, and our accessories can be ordered separately.

Q3. ls there any stock available for the delivery time of orders and sample orders?

1-5 units of stock products will take approximately 5 days, and multiple units or customized products will be negotiated based on your order specifications and quantity.

Q4.Can l take samples for market testing?

Yes. Sample orders can be used for quality inspection and market testing.

Q5. What are your payment terms?

Payment methods:T/T, L/C at sight,WeChat, Paypal,Trade Assurance, Alipay, Applepay, VISA,UnionPay,etc.

Q6. What are your after-service terms?

Remote warranty for one year, quality issues, free accessories provided, consumable accessories are not covered by the warranty.

Q7. How many types of plugs are there to choose from?

Australian plug,English plug, American plug,European plug,etc., customized according to your needs.

Q8. What material is the packaging box made of?

Our ordinary machines are packed with 5 layers of Mica and foam. We can also customize cardboard boxes for you

Q9.How does your factory do quality control?

We attach great importance to quality control from beginning to end. Each product undergoes 100% comprehensive testing before packaging and shipping.

Q10.What are your payment terms?

100% full payment before production.

Copyright © by Changzhou Jinkun Food Machinery Co., Ltd. - Privacy Policy